Plastic box packaging technology holds immense significance in the packaging industry. This technique enhances product appeal and ensures protection. Various advanced technologies elevate packaging standards. Gold foil stamping and UV protection are some examples. Packaging plays a crucial role in product presentation. It safeguards products from damage. Businesses gain a competitive edge through superior packaging. Consumers prefer visually appealing and durable packaging. Investing in quality packaging boosts brand reputation. Companies should prioritize innovative packaging solutions. The industry must focus on sustainable practices. Effective packaging leads to increased customer satisfaction.

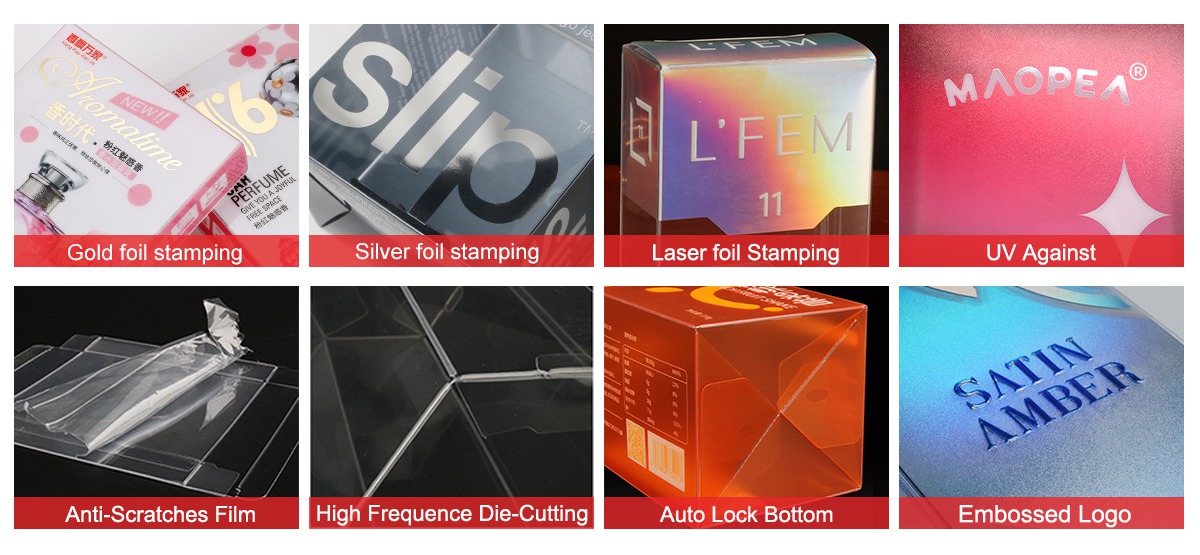

Gold foil stamping enhances the visual appeal of packaging. This technique adds a luxurious touch to plastic boxes. Brands use gold foil stamping to create a premium look. The process involves applying a metallic foil to the surface. Heat and pressure secure the foil onto the packaging. This method increases brand recognition and customer attraction.

Silver foil stamping offers a sleek and modern appearance. Companies choose silver foil for its reflective quality. The stamping process mirrors that of gold foil. Silver foil stamping provides a sophisticated finish. This technique elevates the product's perceived value. Businesses benefit from increased consumer interest.

Laser foil stamping introduces precision and detail. This technology uses lasers to apply foil designs. The method allows for intricate patterns and logos. Laser foil stamping offers versatility in design options. Companies achieve unique branding with this technique. The result is a striking and memorable package.

UV protection safeguards products from harmful rays. Exposure to UV light can damage packaged goods. Plastic box packaging techniques incorporate UV-resistant materials. These materials prevent discoloration and degradation. UV protection extends the shelf life of products. Consumers receive items in optimal condition.

Anti-scratch films preserve the integrity of packaging. Scratches can detract from a product's appearance. Plastic box packaging techniques include protective films. These films resist abrasions and maintain clarity. Brands ensure their packaging remains pristine. Customers appreciate the attention to detail and quality.

Plastic packaging relies on various materials to meet diverse needs. PET, PVC, and PP are common choices for plastic boxes. Each material offers unique benefits for packaging solutions. PET provides clarity and strength, ideal for showcasing products. PVC offers flexibility and durability, suitable for protective packaging. PP resists heat and chemicals, ensuring safe storage. Businesses must select the right plastic to enhance product presentation.

Material choice directly affects packaging quality. High-quality plastics ensure durability and protection. Strong materials prevent damage during transit and handling. Clear plastics enhance product visibility and appeal. Durable packaging maintains product integrity over time. Quality materials boost consumer confidence and satisfaction. Brands gain a competitive edge with superior packaging solutions. Investing in the right materials enhances brand reputation.

Advanced printing methods transform plastic box packaging techniques. Businesses use these methods to captivate consumers. Vibrant colors and intricate designs elevate packaging appeal. Brands achieve a distinct identity through unique graphics. High-quality prints enhance the overall product experience. Consumers associate visually appealing packaging with premium products. Advanced printing increases brand recognition and loyalty.

Digital printing leads the way in modern packaging. This method offers precision and speed. Companies benefit from reduced production times. Digital printing allows for customization and flexibility. Brands can tailor designs to specific campaigns or seasons. Offset printing remains a popular choice for large volumes. This technique provides consistent quality and sharp details. Flexographic printing suits various materials and surfaces. Businesses use flexography for cost-effective solutions.

Several brands have revolutionized their packaging with advanced printing. A leading cosmetics company embraced digital printing. The company launched a limited edition line with personalized designs. Sales increased by 25% due to the unique packaging. A beverage brand used flexographic printing for eco-friendly labels. The brand's commitment to sustainability attracted new customers. A tech company utilized offset printing for its premium product line. The high-quality packaging reinforced the brand's luxury image.

The packaging industry must address the pressing issue of single-use plastic waste. Companies should prioritize the development of reusable and recyclable packaging solutions. Innovative designs can minimize waste and promote environmental responsibility. Consumers increasingly demand sustainable options. Brands that offer eco-friendly packaging gain a competitive advantage. Reducing plastic waste aligns with global sustainability goals. Businesses can enhance their reputation by adopting green practices. The shift towards sustainable packaging benefits both the environment and the economy.

Technological advancements drive the evolution of plastic packaging. New materials and processes improve packaging efficiency and sustainability. Biodegradable plastics offer an alternative to traditional materials. These innovations reduce environmental impact and support circular economies. Smart packaging technologies enhance product tracking and consumer engagement. Interactive features provide valuable information and improve user experience. Companies that embrace technology lead the way in modern packaging solutions. Investing in cutting-edge technologies ensures long-term success and relevance.

Plastic box packaging techniques hold immense value in the packaging industry. These techniques enhance product presentation and ensure protection. Innovation and sustainability drive the future of packaging. Businesses must embrace advanced methods to stay competitive. Eco-friendly practices benefit both the environment and brand reputation. Companies should prioritize sustainable solutions. Investing in innovative packaging leads to increased customer satisfaction. The industry must adopt these practices for long-term success.